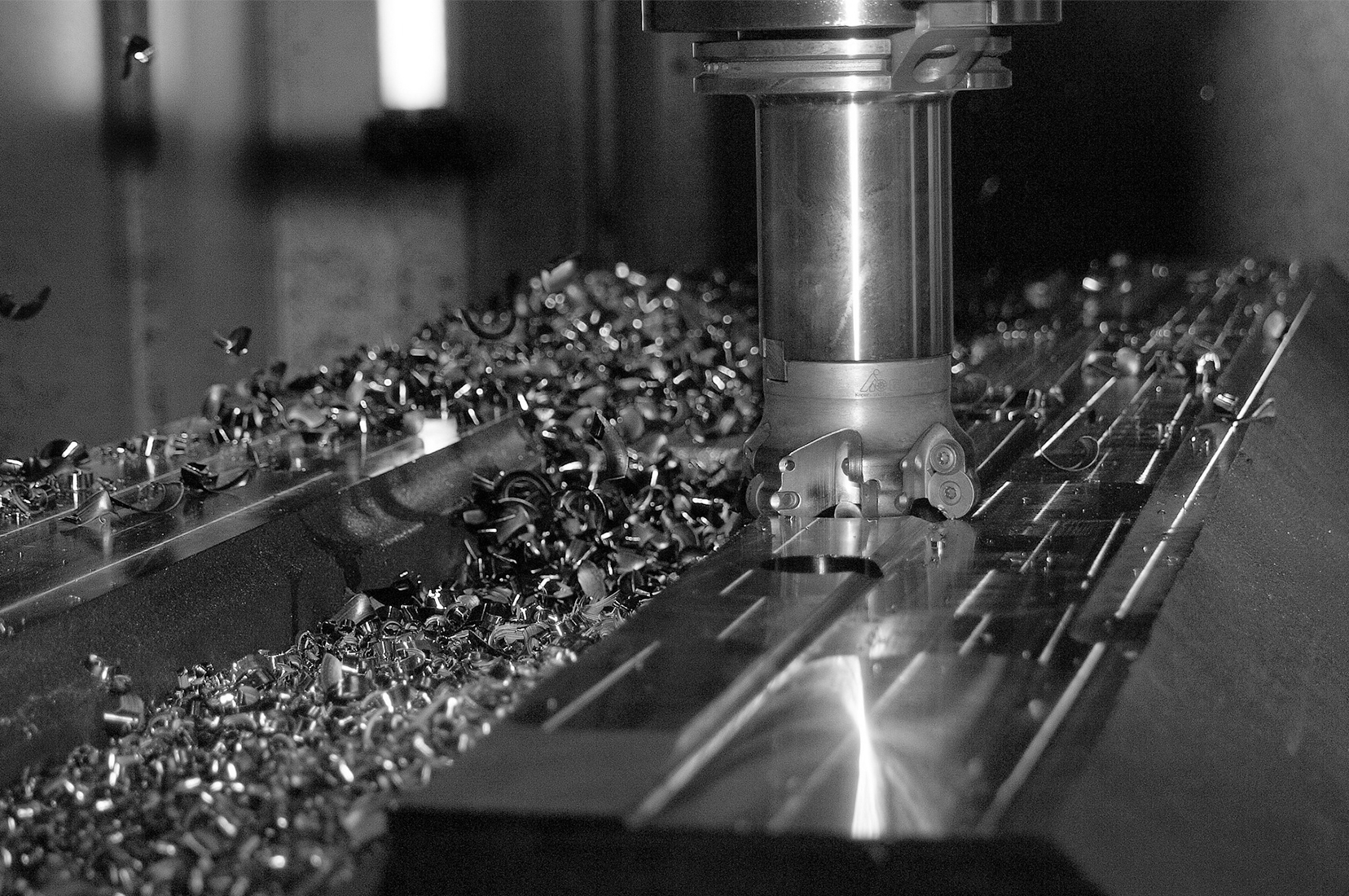

The purpose of machine tool debugging is to check whether the machine tool installation is stable, and whether the transmission, control, control and other systems are normal and sensitive and reliable.

The commissioning and commissioning work is carried out in the following steps:

According to the requirements of the manual to a lubricating point of oil, into the hydraulic tank to meet the requirements of the hydraulic oil, connected to the air source. Power on, each component is powered separately or each component after a power test, and then full power supply. Observe whether each component has an alarm, whether the manual observation of each component is normal, and whether the safety devices work. Even all aspects of the machine can be operated and moved. After the initial operation of the machine tool, the geometric accuracy of the machine tool is roughly adjusted, and the relative position of the main moving parts and the main machine is adjusted after disassembly. Align the manipulator, tool store, exchange table, position, etc. After these tasks are completed, the anchor bolts of the main engine and all accessories can be filled with quick-drying cement, and the reserved holes of each anchor bolt can be filled flat. After debugging, prepare various testing tools, such as precision level, standard square meter, parallel square tube, etc. Fine-adjust the level of the machine tool, so that the geometric accuracy of the machine tool can reach the allowable error range, using multi-point cushion support, the bed is adjusted to the level in the free state to ensure the stability of the bed after adjustment.

Adjust the position of the machine hand in relation to the main shaft by manual control, using the adjusting rod. When installing the maximum weight tool handle, it is necessary to automatically exchange the position of the tool library to the spindle several times to achieve accuracy and no impact. Move the workbench to the exchange position, adjust the relative position of the tray station and the exchange workbench, so as to achieve the smooth automatic exchange of the workbench, and install the maximum load of the workbench, and carry out multiple exchanges.

Check whether the set parameters of the numerical control system and the programmable controller PLC device conform to the specified data in the random data, and then test the main operating functions, safety measures, and the execution of common instructions. Check the working condition of accessories, such as machine lighting, cooling shields, various shields, etc.

After the installation and debugging of a machining center, due to its many functions, after the installation, it can be automatically run for a long time under a certain load, and it is more comprehensive to check whether the function of the machine tool is complete and stable. The operation time can run 8 hours a day for 2 to 3 days or every 24 hours for 1 to 2 days. Continuous operation can use the test machine program.